What is an offshore reefer container?

Offshore reefer containers (also known as Offshore refrigerated containers) are used within the shipping industry to transport temperature-sensitive products that need refrigeration. Within the oil and gas industry, they are also popularly known as “skids.”

MGS offshore reefer containers have data monitoring systems, automated temperature and ventilation control, offering complete reliability in supplying perishable products to offshore locations.

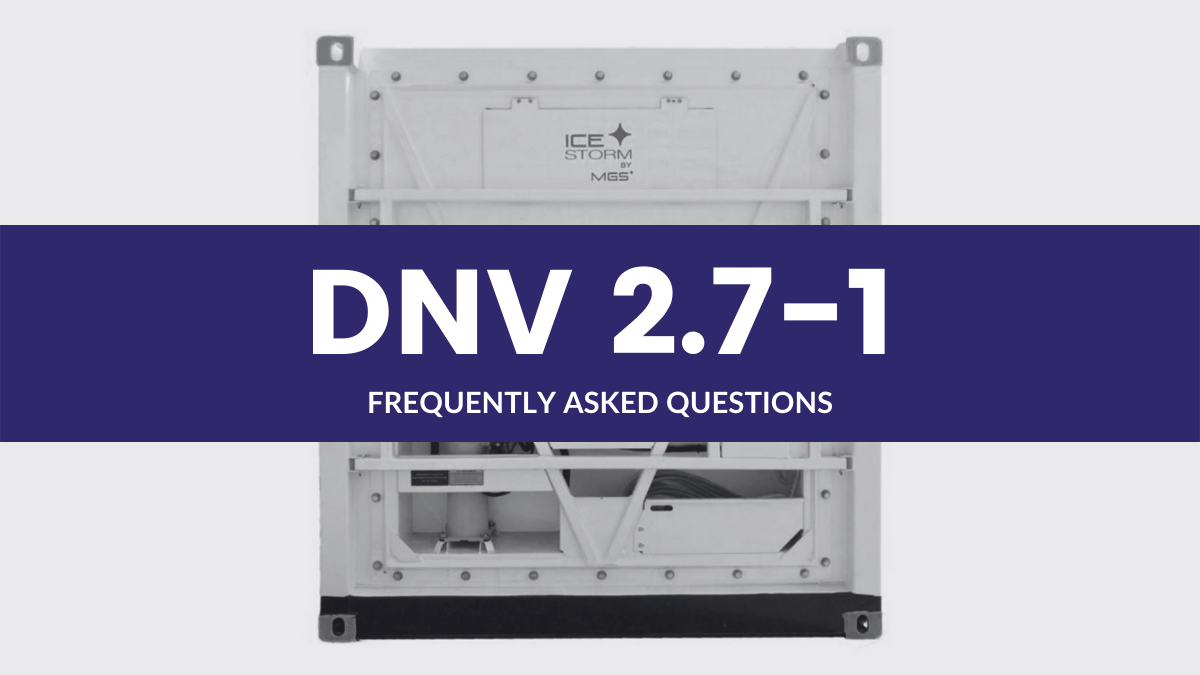

At MGS Offshore, we offer two DNV-certified reefer container models:

Ice Wave (8 feet)

Ice Storm (10 feet)

Uses of offshore refrigerated containers

Our automated refrigerated containers can maintain temperature ranges as low as -60 degrees Celsius (-76 degrees Fahrenheit). This is extremely important in the transportation of products like pharmaceuticals, seafood, meats, fresh fruits, vegetables, flowers, and certain chemicals.

COST SAVING FACTORS

Get a Free Consultation

ICESTORM & THERMO KING

ICESTORM employs technology not used elsewhere on our refrigerated storage units. By virtue of its microprocessor controller, which integrates solid state electronics and enormous processing power, it can far more accurately ride the “sweet spot” of the ideal refrigeration cycle.

In collaboration with TOP NOTCH SCIENTIST, we invented our own insulation material that contributed to the improvement of insulated air freight containers with dry ice as a refrigerating source by means of model calculations and climate chamber tests.

On top of that, MGS has established a closer partnership with THERMO KING, which eventually led to tremendous improvements in our reefer container technology. As a result, we will deliver the most advanced innovations in the reefer container market and bring greater value to consumers. All our offshore reefer containers are certified with DNV 2.7-1, EN-12079 and ISO 10855.

With this extraordinary collaboration, we are offering our customer the best elements of two expert brands in harmony. Through this opportunity, we aim to enhance the quality of our offshore reefer containers and continue to develop more advanced technology with exceptional innovation with THERMO KING.

Consistency is key to reliable offshore containers. Throughout the journeys around the world, temperatures have to be predetermined and maintained for optimal services. To that, our ideal offshore refrigerated containers are catered to provide customers with end-to-end services that meet all your needs.

Get a Free Consultation

Bringing DNV 2.7-1 Certified Offshore Reefer Containers Across the Globe

Our expertise in offshore reefer container solutions has been sought after by prominent oil and gas rigs across the globe.

We pride ourselves in delivering unparalleled quality, reliability, and safety. Our containers are meticulously designed to meet the rigorous demands of the offshore industry, ensuring your perishable goods remain in optimal condition, regardless of the environment.

As we strive to set the benchmark in the industry, here are some of the countries where we offer our offshore reefer container services.

- Europe: Norway, Italy, Scotland, UK, Denmark, Netherlands, France, Germany, Romania, Kazakhstan, Azerbaijan

- Asia: Taiwan, Myanmar, Thailand, Hong Kong, Vietnam, Singapore, Brunei, Saudi Arabia, Qatar

- Africa: Senegal, Ghana, Nigeria, Gabon, Angola, South Africa

- Americas: Canada, Rhode Island, Louisiana (USA), Mexico, Trinidad, Guyana

- Oceania: Australia, New Zealand

Don’t see your location? Contact us for further enquiries.

MGS Offshore’s freezer containers are the best in the market. We pride ourselves on providing the highest quality reefer containers to our clients and have put the following in place:

CONTAINER FLOOR / WALL INFORMATION

The refrigerated container’s base frame is composed of corrugation type steel base frame and “T” section aluminum floor rail with Insulation.

The T-bar floor is made of aluminium and designed to optimize the airflow in the container. The new generation of container side lining panels (walls) are made of polypropylene material. This material ensures maximum strength, with a reduced risk of foam delamination.

The insulation material used in the reefer container is patented environment-friendly foam insulation, meeting tomorrow’s environmental requirements.

DATA LOGGER

Our reefer refrigeration keeps track of vital data and information of reefers to ensure actions can be taken swiftly by operators.

- Supply air temperature

- Return air temperature

- Ambient temperature

- Cargo temperature

- Humidity level

- Tuning operations

- Modifying the parameters

- Interventions

- Breakdowns

- Alarms

HUMIDITY

The relative humidity level is important when it comes to controlling the quality of your products. Container cooling and humidity affects the shelf life of fruits and vegetables – and thus their condition upon arrival.

The recommended relative humidity for most fresh fruit and vegetables is between 85% and 95%, depending on the variety. This level of humidity is generated automatically in a reefer container, where correct ventilation and packaging is applied. De-Humidification can be applied to products which are sensitive to high humidity.

Ice Storm reefer containers can dehumidify the air in the range of 65% to 85%.

- Too high levels of humidity may cause mould and/or fungi development.

- Too low levels of humidity may result in dehydration/weight loss and further lead to wilt and/or shrivel.

BEST INSULATION MATERIAL

In collaboration with TOP NOTCH SCIENTIST, we invented our own insulation material that contributed to the improvement of insulated air freight containers with dry ice as a refrigerating source by means of model calculations and climate chamber tests.

PERFECT FRESH UPON ARRIVAL

Our ICE STORM reefer containers extend the shelf life of your fruit and vegetables by slowing down the ripening process during transit. ICE STORM is particularly suited to avocados, bananas and asparagus (daily food) because it maintains an ideal blend of oxygen and carbon dioxide within the reefer unit.

FOOD SAFETY

- Strict hygiene rules enforced on dairies, farm process plants etc.

- Limited rules or policies directed towards maritime transport of food stuffs

- No definition of “clean”

- The future is different (by definition) and food safety will be an important topic in the Oil & Gas industry

DNV 2.7-1 STANDARD ICE STORM REEFER

Adding to the safety of MGSOffshore Refrigerated, refrigerated containers (designed to meet the ATEX Directive) is the DNV containers. The ICE STORM containers are certified to EN12079 and DNV 2.7-1. The Offshore Refrigeration Units are mounted to these containers.

DNV certified containers (also known as Offshore Containers) are used primarily in the oil and gas industry because of their ability to withstand the harsh environment and handling of the offshore industry. Due to the dangerous nature of the oil industry, these shipping cooling containers are subject to many more regulations and must undergo a strict certification process to ensure the safety of personnel working on the oil rigs, oil tankers, as well as the environment.

As refrigerated offshore container manufacturers, MGS Offshore Refrigeration (ICE STORM) and DNV containers are certified to DNV 2.7-1/EN12079. This makes the Offshore Refrigerated Container the ideal solution for the global offshore oil and gas industry.

DIFFERENCES BETWEEN OFFSHORE REEFER CONTAINER AND ISO REEFER CONTAINER

MGS Offshore Reefer Container VS Common ISO Reefer Container

Offshore Reefer Containers specially tailored to meet Oil & Gas Industry requirements.

8 ft. & 10 ft. Offshore Reefer Container

Common ISO Reefer Container not designed for Oil & Gas Industry requirements

20 ft. & 40 ft. ISO Reefer Container

Offshore Reefer Containers specially tailored to meet Oil & Gas Industry requirements.

8 ft. & 10 ft. Offshore Reefer Container

Common ISO Reefer Container not designed for Oil & Gas Industry requirements

20 ft. & 40 ft. ISO Reefer Container

Offshore Reefer Containers are certified with DNV 2.7-1,

EN 12079 and ISO 10855

OUR LATEST NEWS

TESTIMONIALS

FAQ on Offshore Refrigerated Containers

DNV stands for Det Norske Veritas, an independent organization that provides certification for reefer containers. All refrigerated containers available for purchase and rental at MGS Offshore are DNV 2.7-1 certified.

Reefer containers are used for shipping temperature-sensitive products. These include:

- Pharmaceuticals

- Cheese

- Sea food

- Fruits and vegetables

- Meats

- Flowers

- Certain chemicals

MGS Offshore offers two models of reefer containers – DNV Certified 8ft Ice Wave and DNV Certified 10ft Ice Storm. Read here for more information on reefer dimensions and specifications.

Offshore reefer container cost depends on the size and model selected. Click here to request a quote for your preferred model with MGS Offshore.

Reefer containers are reusable units and renting one is often a more cost-effective option for organizations that may have budget constraints. At MGS Offshore, reefer container renting is a cost-effective solution since there is no minimum rental period.

Reefers are designed for multiple reuses for transporting goods within the cold chain. However, it is important to regularly maintain them to avoid damage or malfunctioning which can further affect the quality of the products being transported.

Various maintenance activities include rust removal, container body fixing, checking door seals, refrigeration units, condensers, evaporators, reefer coils, circulating fans, etc.

Read more on “Offshore reefer container maintenance guide.”

At MGS, we offer 24/7 availability, complete operational support and maintenance on demand for all our rental products.

Reefer tracking systems help freight operators to check real-time location based on GPS data. These systems are often combined with sensors that help report any temperature deviations to the monitoring system.

A reefer tracking system helps to reduce operational costs during sea freight by cutting the risks associated with cargo loss and spoilage.

Read more on “How reefer container tracking system saves you operational costs?”